Our Service –

individual &

reliable

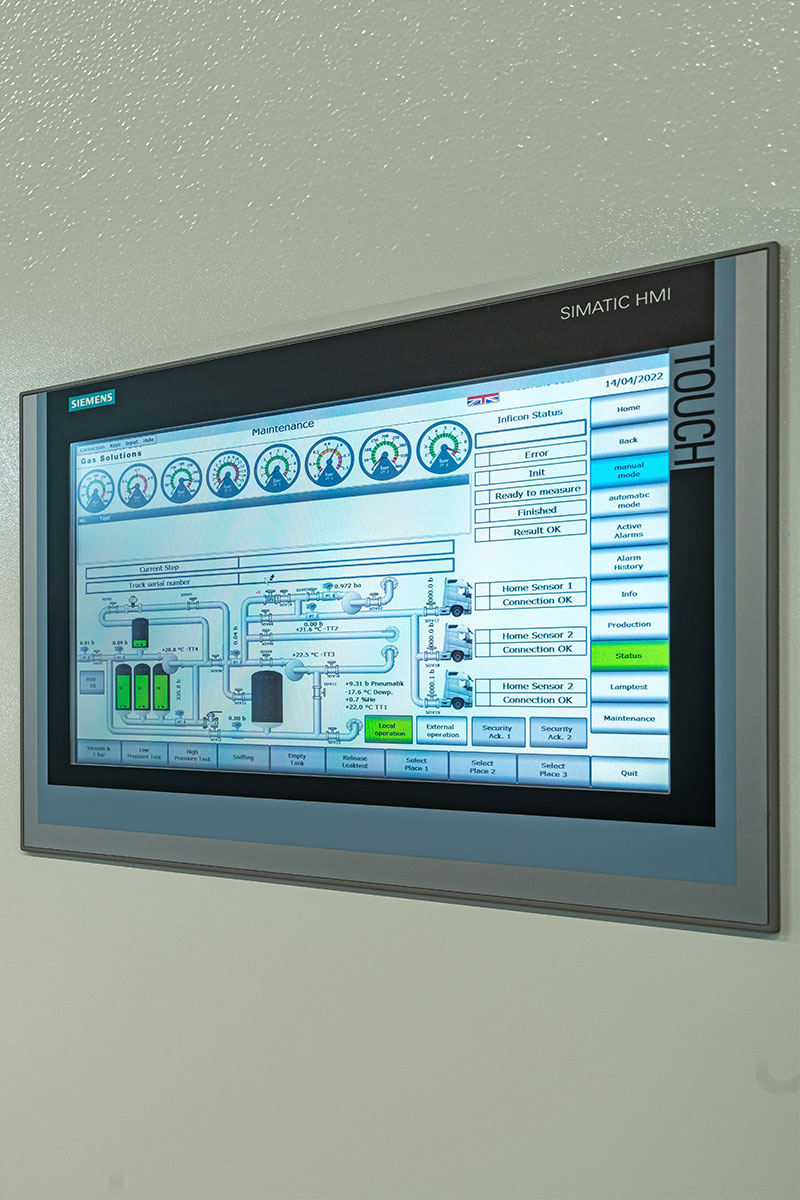

Maximator Gas Solutions not only stands for innovation and quality products, but also for efficient functionality, durability and safety of components manufactured and plants serviced by us. Our specially trained service technicians are available 24/7 and ensure that error messages or functional defects are dealt with quickly and reliably.

To make sure you can focus on your day-to-day business, we are happy to tailor a service package to suit your individual requirements. Please request further details.